Projekt: Fehmarn Belt Innovation

NordBau Smart Constructions

Prof. Dr.-Ing. Herrmann I Brodmann

DesignBuild Semester Project I Bachelor & Master Architecture I SoSe 2024 I 24 Students I 7 Companies

The novel teaching format, NordBau Smart Constructions, aims to connect architecture students with innovative companies in the construction industry. During this collaborative exchange, students are tasked with developing ideas for practical problems or research-related questions relevant to the particular industry. They receive support from both the companies and the instructors in selecting, evaluating, and refining their various concepts. Coupled with the DesignBuild teaching approach, the digitally developed projects are tested for their physical feasibility at a 1:1 scale.

The resulting prototypes challenge and enhance the students' understanding of geometry, their engagement with construction, and their craftsmanship and digital fabrication skills. Simultaneously, the collaboration with real companies and the addressing of actual issues form a meaningful task. Through this process, students independently and interactively learn to manage communication, agreements, procurement, time and project management, and compromise.

The semester project took place in the summer semester of 2024 under the direction of Prof. Dr.-Ing. Herrmann and Anton Brodmann. A total of 25 students, divided into 9 groups, participated in the project from the courses „Sonderthema der Architektur 2" (Bachelor Architektur) and "Sonderthemen Architektur“ (Master Architektur). The project is made possible through the partnership in the Fehmarn Belt Innovation Project, a German-Danish Interreg-project. The University of Applied Sciences Lübeck, represented by the RoboLab, along with the partner university Zealand from Naestved, Denmark, is responsible for the Smart Construction Sector. Through this collaboration, the project involved five German and two Danish companies.

You can view the exhibition pieces from September 4th to 8th, 2024, at NordBau in Neumünster. Our joint exhibition stand is located in Hall 1, near the west entrance.

Are you interested in participating in the next NordBau Smart Constructions in 2025 (Winter semester 2025, 03/2025-09/2025)? Feel free to contact us via email.

- 3D Printing with Seaweed and Clay - Collaboration with Baltic Materials, Kiel (GER)

Project by Sonja Rudolph, Leander Schmitz and Fabienne Zersch

Supported by Marc Wejda and Tjark Ziehm from Baltic Materials, Kiel (GER)

The objective was to determine whether seaweed exhibits similar or superior properties compared to straw when combined with clay. Initially, smaller experiments were conducted to ascertain which type of seaweed (long, short, or powdered) works best in a specific concentration of clay and water, and to identify any potential challenges. The experiments revealed that powdered seaweed exhibited the most favorable properties, as it counteracts cracking in the clay and consequently increases surface tension. The long seaweed often became entangled in the feed screw, rendering the results inconclusive.

Subsequently, a form was programmed for the robotic arm with a direct extruder for pasty materials using Rhino and Grasshopper software. The form was designed to be stable in itself, yet challenging for the seaweed-clay mixture due to its convex path designs. Whether the print was successful? This remains to be seen, as the clay is still drying.

- ETICS/WDVS Alternatives - Collaboration with Briiso, Kalundborg (DK)

Project by Felix Denken and Claas Lüneberg

Supported by Lars Andersen from Briiso, Kalundborg (DK)

The company Briiso's special field is an External Thermal Insulation Composite System (ETICS, german: WDVS) that is based on the combination of insulation and brick slips. The students project considered how a future-oriented ETICS system might look and how it could address the challenges of our time. Two variants were developed: one focused on the issue of material purity, while the second variant emphasized ecological aspects.

- Privacy Screen 2.0 - Collaboration with Tischlerei Eigenstetter, Rehna (GER)

Project by Miriam Kranz, Anne Neukirchen and Fatma Saricam

Supported by Martin Eigenstetter from Tischlerei Eigenstetter, Rehna (GER)

Together with the company German Domes, which builds transparen, lightweight domes for different uses, the task to design a flexible interior privacy screen was defined. The design of the semi-dome-shaped privacy and sunshade is based on the geodesic dome and is divided into three segments that can be moved along rails. The structure stands 1.86 meters tall and, when fully extended, covers a radius of 180°. The movable wings allow the privacy screen to be manually adjusted to meet the needs of users.

Originally intended for the interior of a dome, the visualisations suggest that suitable furniture can complement the protection provided by the screen. The construction consists of planar elements with thicknesses of 30 mm and 20 mm, which are machine-milled. The rails are supported by ball bearings to reduce friction and facilitate the opening and closing of the segments. The fabric can be easily removed using sewn-in Velcro fasteners.

- Reed Noise Barrier - Collaboration with Hiss Reet, Bad Oldesloe (GER)

Project by Avin Ahmad and Ali Al-Attar

Supported by Jan Witt and Sven Bormann from Hiss Reet, Bad Oldesloe (GER)

This innovative concept involves constructing a multifunctional pavilion made from natural reed, which offers numerous benefits and blends seamlessly into the natural environment. The pavilion serves as an effective noise barrier, a gathering point, and an insect hotel. Its design integrates effortlessly into the natural surroundings, enhancing the environment.Reed naturally possesses soundproofing qualities that reduce noise from roads, trains, and other sources. The rustic appearance and inherent warmth of the material create an inviting and cozy atmosphere, making it ideal for gardens, parks, and nature-oriented recreational areas. Reed is a renewable and environmentally friendly material that can be harvested sustainably. It helps reduce the ecological footprint and, with its authentic appearance, complements various architectural styles, thus highlighting the natural aesthetic of the surroundings. The pavilion provides ecological value by serving as a habitat for birds and insects, thereby contributing to biodiversity. Reed offers suitable shelters for various insect species, which often struggle to find appropriate nesting places in modern landscapes. It is highly versatile, functioning as a noise barrier, a decorative element, a meeting place, or a relaxation spot. Its flexibility and adaptability to different designs make it a valuable component of creative and sustainable building projects.

- The Compostable House - Collaboration with Planterial, Kiel (GER)

Project by Anne Kleiber, Christopher Meyn and Simon Tutschilowski

Supported by Mika Siponen and Hannes Stuhr from Planterial, Kiel (GER)

A Proposal for More Sustainable Construction Methods in the Era of Climate Change

The Compostable House is designed without harmful substances and primarily made from natural and untreated materials. In theory, most of the components can be discarded in the forest after deconstruction, where they would naturally decompose. The remaining materials are still suitable for reuse.The foundation of this concept is the hemp-based panel material from Planterial. This startup is specialised in producing hemp panels without formaldehyde or similar harmful substances. The panels are pressed using a plant-based protein adhesive, making them deconstructable without leaving additional construction waste. This concept of compostable panels inspired the design of the Compostable House. The entire interior is planned to be constructed using these hemp panels.

- Hemp Acoustic Panels - Collaboration with Planterial, Kiel (GER)

Project by Dustin Buddenberg, Fabian Nowatzky and Benjamin Volk

Supported by Mika Siponen and Hannes Stuhr from Planterial, Kiel (GER)

After evaluating numerous ideas for further developing Planterial's hemp panels, the decision was made to create various acoustic panels. These acoustic panels, made from hemp shives, offer an environmentally friendly alternative to conventional acoustic panels. Hemp shives grow quickly and can be harvested multiple times a year, whereas wood, depending on the species, takes 15 to 30 years to mature. This makes hemp acoustic panels a sustainable solution for sound insulation and optimization in buildings.

- Future Refuel - Collaboration with Schütt Holzbau, Landscheide-Flethsee (GER)

Project by Jannis Goik, Marie Ketelsen and Leon Lange

Supported by Tim-Niklaas Alpen and Max Müller from Schütt Holzbau, Landscheide-Flethsee (GER)

This concept offers an approach to minimising the space requirements of rest and fueling stations while focusing on the planning of e-mobility. By combining refueling, parking, and resting, the design approach gains greater significance in the overall concept. The displayed section illustrates the apex of an arch support featuring three rafter connections with concealed connectors, as well as a hinged joint with a tension plate and dowel pins.

- FlexiExpo - Collaboration with Schütt Holzbau, Landscheide-Flethsee (GER)

Project by Svea Lange and Ruben Prüße

Supported by Tim-Niklaas Alpen and Max Müller from Schütt Holzbau, Landscheide-Flethsee (GER)

Reimagining Exhibition Stands – FlexiExpo – The Flexible Exhibition Stand

Delivery, Setup, Unpacking, Assembly.

- Flexible Living - Collaboration with WOHN A/S, Herlufmagle (DK)

Project by Berfin Havuc, Franka Hillmer and Johanna Ulbrich

Supported by Morten Bove and Matúš Uríček from Wohn A/S, Herlufmagle (DK)

This project is based on the specialised large-format 3D printing of recycled polymer and wood fiber by WOHN. These new possibilities give rise to a design that maximises this flexibility and makes living in small spaces versatile. Using plug connections that fit together without glue, the building can be completely disassembled into its individual parts and reassembled as needed. The floor plate and roof are also to be assembled using a plug-in system. They are connected by beams that extend from the floor to the roof. This allows for quick and straightforward on-site assembly of the building. The building’s shape can be combined in various ways, creating adaptable living spaces. The modules can be joined to form individually habitable units or, by removing specific wall sections, expanded into larger living areas. Stackability opens up even broader possibilities for additive combinations.

The prototype highlights the unique feature of the system: the printing directions of the individual components. The floor and ceiling are printed in a direction opposite to that of the walls, which makes the connector system so innovative. A beam that extends from floor to ceiling connects the individual parts and allows for straightforward assembly as well as flexible and easy reconfiguration. Additionally, the prototype demonstrates the insulation method of the components.

Discover Denmark Excursion

Prof. Dr.-Ing. Herrmann I Prof. Dr.-Ing. Spaeth I Prof. Locher I Prof. Lippe I Brodmann

Excursion I Master Architecture I SoSe 2024 I 22 Students

From May 27th to 31st, 2024, the “Discover Denmark Excursion” took place as part of the Master’s program in Architecture at the University of Applied Science Lübeck. The excursion was led by Professors Michael Herrmann and Benjamin Spaeth (both specialised in Digital Construction), Professor Heiner Lippe (specialised in Sustainable Construction), and Professor Michael Locher (specialised in Building in Existing Contexts), along with research associate Anton Brodmann (Realbaulabor, RoboLab, and Fehmarn Belt Innovation Project).

Supported by the network of the German-Danish Interreg project "Fehmarn Belt Innovation" (FBI), a multifaceted program on the theme "Transformations of Harbors" was offered. The excursion journeyed from Naestved, located in southern Sjaelland, through Roskilde to Copenhagen, concluding with a network event in Rødby. Like the Interreg project itself, the trip focused on the Fehmarnbelt Tunnel currently under construction and its future potential for enhancing the connection of life and work in the Fehmarnbelt region.

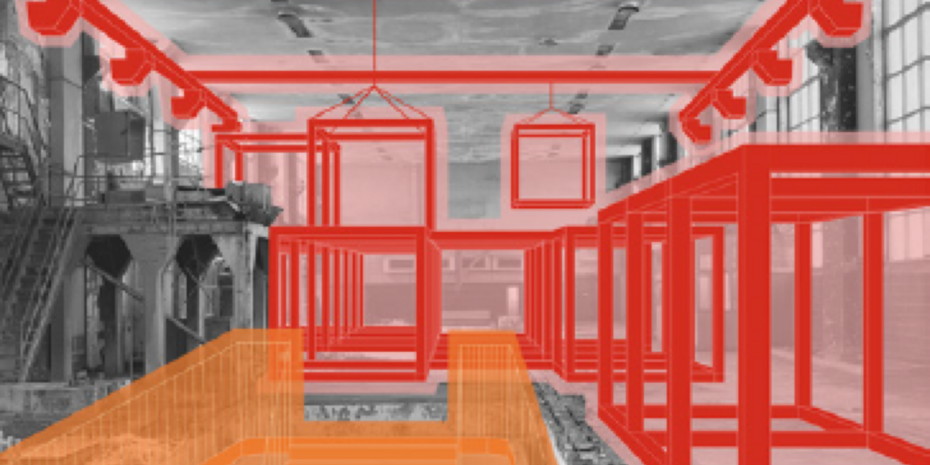

- 27.05.2024 Naestved: Maglemølle, Zealand Academy

The week began with a visit to the project partner Zealand Academy of Technologies and Business (Zealand) combined with a city tour of the vibrant graffiti scene in the small town. Together with Mathias Munkholm Jensen and Julie Askholm Persson (both from Zealand), the group visited the former industrial site Maglemølle near Naestved Harbor. In the premises of Ressource City and through an on-site visit, the students were introduced to their task for the week: developing an innovative new usage strategy with structural interventions for the main building of the former paper factory.

- 28.05.2024 Roskilde: Hackathon, Roskilde University

On the second day, the group visited Roskilde University (RUC). The day, organised in cooperation with Matt Jon Spaniol and Sune Stourstrup (both from RUC), was designed as an idea generation format. Methods such as scenario planning workshops and practical references presented by Rural Agency were used. The facilities and equipment of RUC's FabLab were available to the student groups throughout the day for the analog (sketches), digital (3D modeling), and physical (prototyping) development of their concepts.

- 29.-30.05.2024 Copenhagen: Nordhavn, Jernebanekredsen, Lendager Group, Carlsberg District, Arkitema

The next two days were spent in Copenhagen. In addition to a guided architecture tour by the DAC through the first phase of the well-known urban development area Nordhavn, the students explored the latest centrally located development area Jernbanebyen (The Railway District) together with Birgitte Clasen from Kobenhavn Kommune. Visits to the architectural firms Lendager Group (with Jan Dankmeyer) and Arkitema (with Tim Bruun) provided insights into the Danish working environment as well as current exciting projects.

- 31.05.2024 Rødby: Network Workshop, Rural Agency

The trip concluded with an invitation from Anna Sofie Hvid (Rural Agency) to participate in a network workshop of the Interreg project BELT on the theme "Ports in the Fehmarn Belt Region - Future, Transformation, and Potential with regard to the Femern Link." This included interesting practical insights through the presentation of current cases from Stubbekøbing (by Stubbekøbing 4850), Neustadt (by Volker Rathje, Elbberg Stadt / Landschaft Hamburg), and Naksov (by Henrik Madsen, Naksov 2030). The excursion's grand finale offered the students the opportunity to present their concepts for the excursion task to an expert audience and a jury in a pitch presentation. The award for the most promising concept went to "Creative MeltingPot for Naestved" by students Fatima Ouahhoud, Joschka Johann Hinrichs, and Johanna Sofia Pohl, which impressed the experts with its clearly formulated usage strategy and independent structural intervention. Morten Pristed from Ervervshus Sjaelland presented the award.

We thank all participants and hosts and look forward to exciting cooperation opportunities in the future!

- Deliveries Design Task Maglemølle Phase 1

The first phase deliveries to the design task at Maglemølle have been prepared during the field trip (28th to 30th of May).

- Deliveries Design Task Maglemølle Phase 2

The second phase deliveries to the design task at Maglemølle have been reworked during the rest of the semester (1st of June to 30th of July).